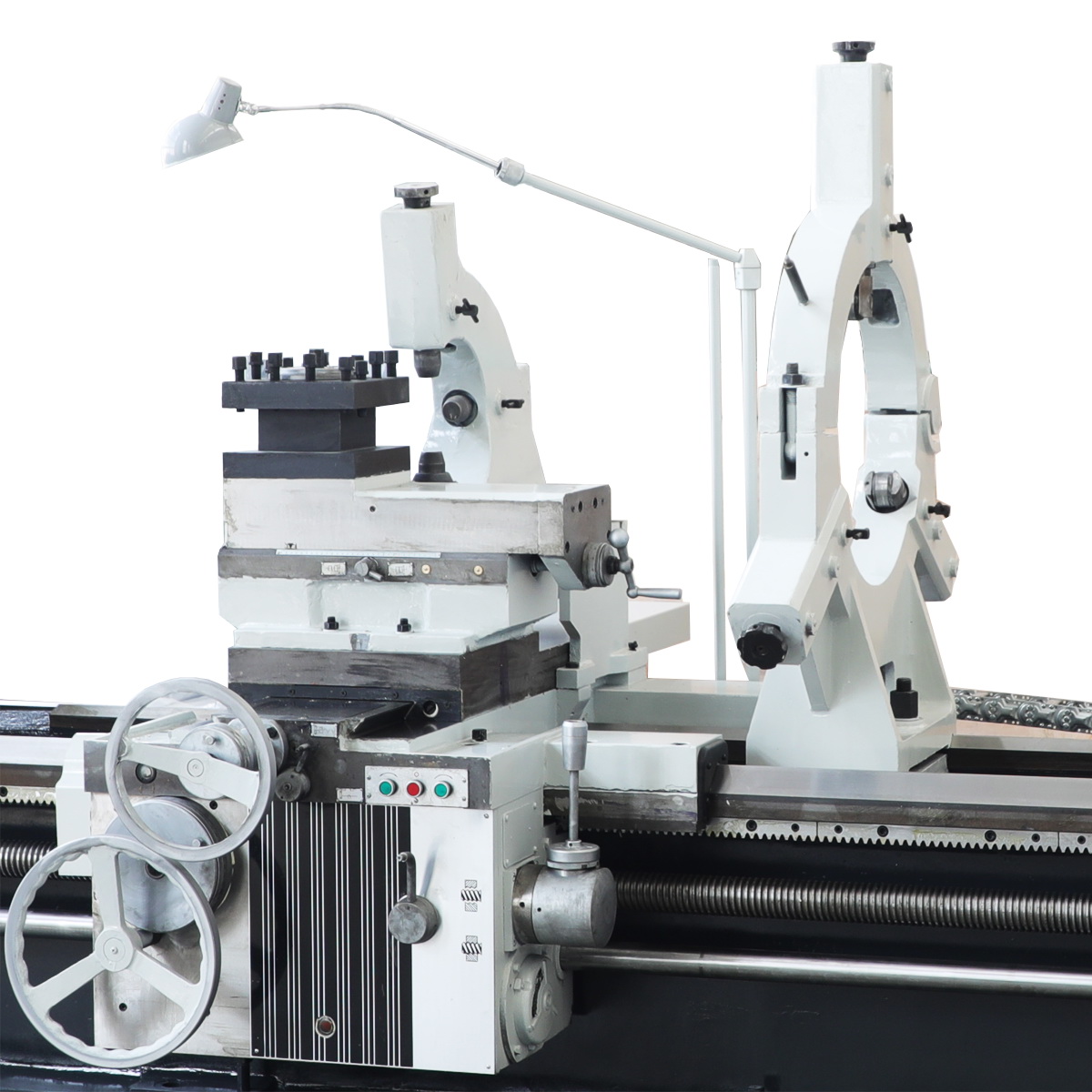

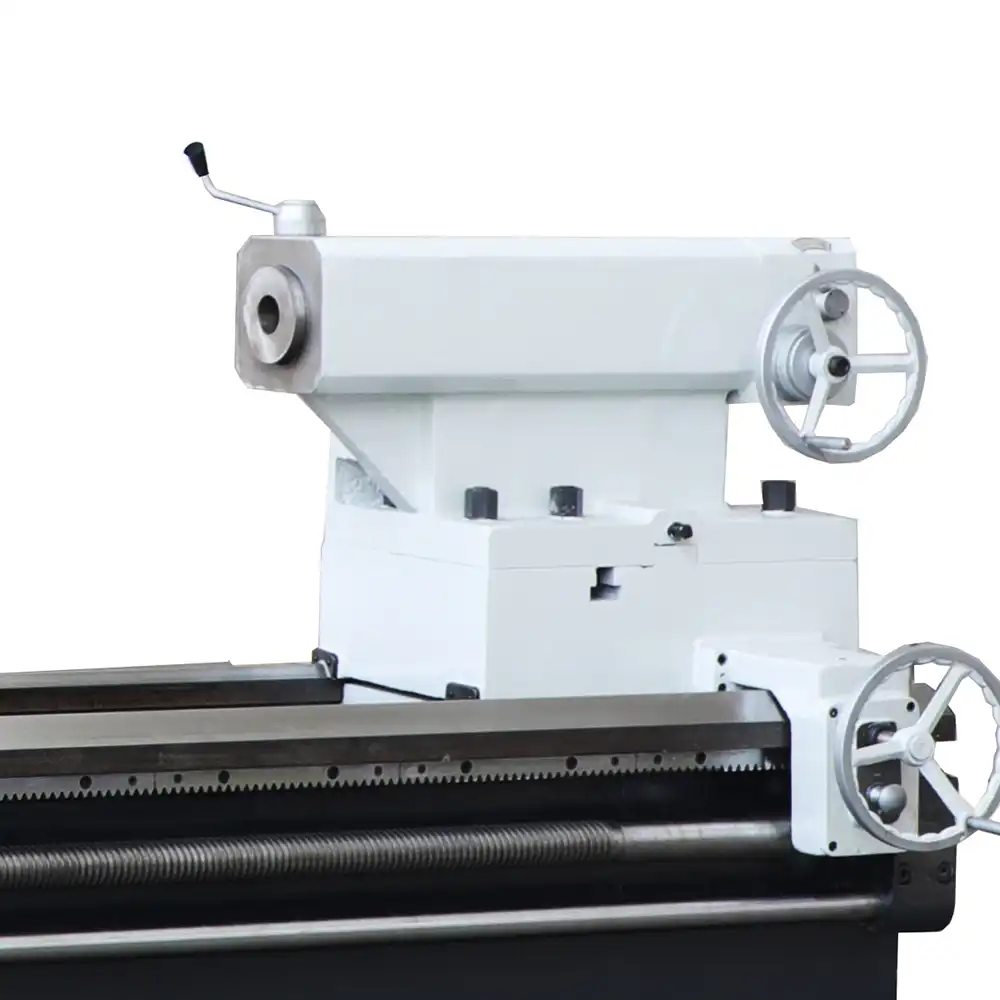

The CW61100B/61125B/61140B/61160B series large lathes have a load capacity of 6 tons and can machine a variety of components including end faces, outer circles, inner holes, as well as metric threads, imperial threads, modulus threads, and pitch threads. The upper tool post can be used for machining short tapers independently, while a combination of the upper tool post and longitudinal feed can be used to machine long tapers. The machine can also handle drilling, reaming, boring, and other processes. With a high power output and strong rigidity, the machine can utilize carbide tools for threading operations and process various ferrous and non-ferrous metals.

Key features include:

-

High-Rigidity Integrated Bed: The bed adopts an integrated casting structure with rationally designed internal ribs for enhanced rigidity. The guideways are treated using medium-frequency quenching and grinding. Anti-creeping guide plates are used on the sliding guide surfaces to optimize the dynamic properties such as friction damping, preventing low-speed creeping.

-

High-Rigidity, High-Precision Spindle: The spindle box employs a symmetric structure to ensure uniform thermal deformation, preventing spindle center misalignment. To reduce thermal deformation, the headstock is lubricated via an oil-bath circulation system. The spindle front end uses a three-support structure with bidirectional angular contact ball bearings, improving precision and enhancing rigidity. The gears inside the spindle box are subjected to quenching and grinding, ensuring accurate transmission and low noise. The spindle maintains stable precision over long periods of operation.