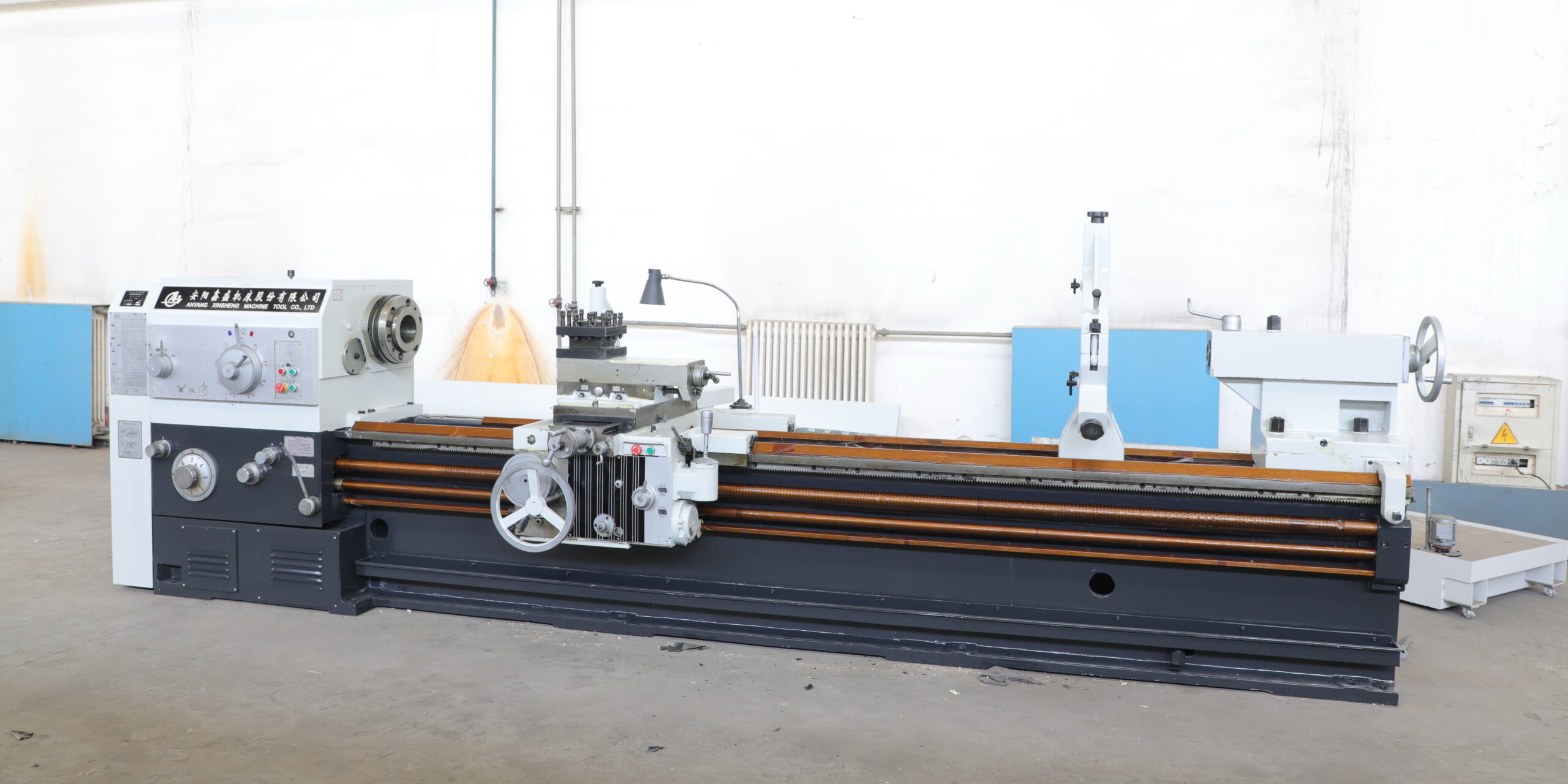

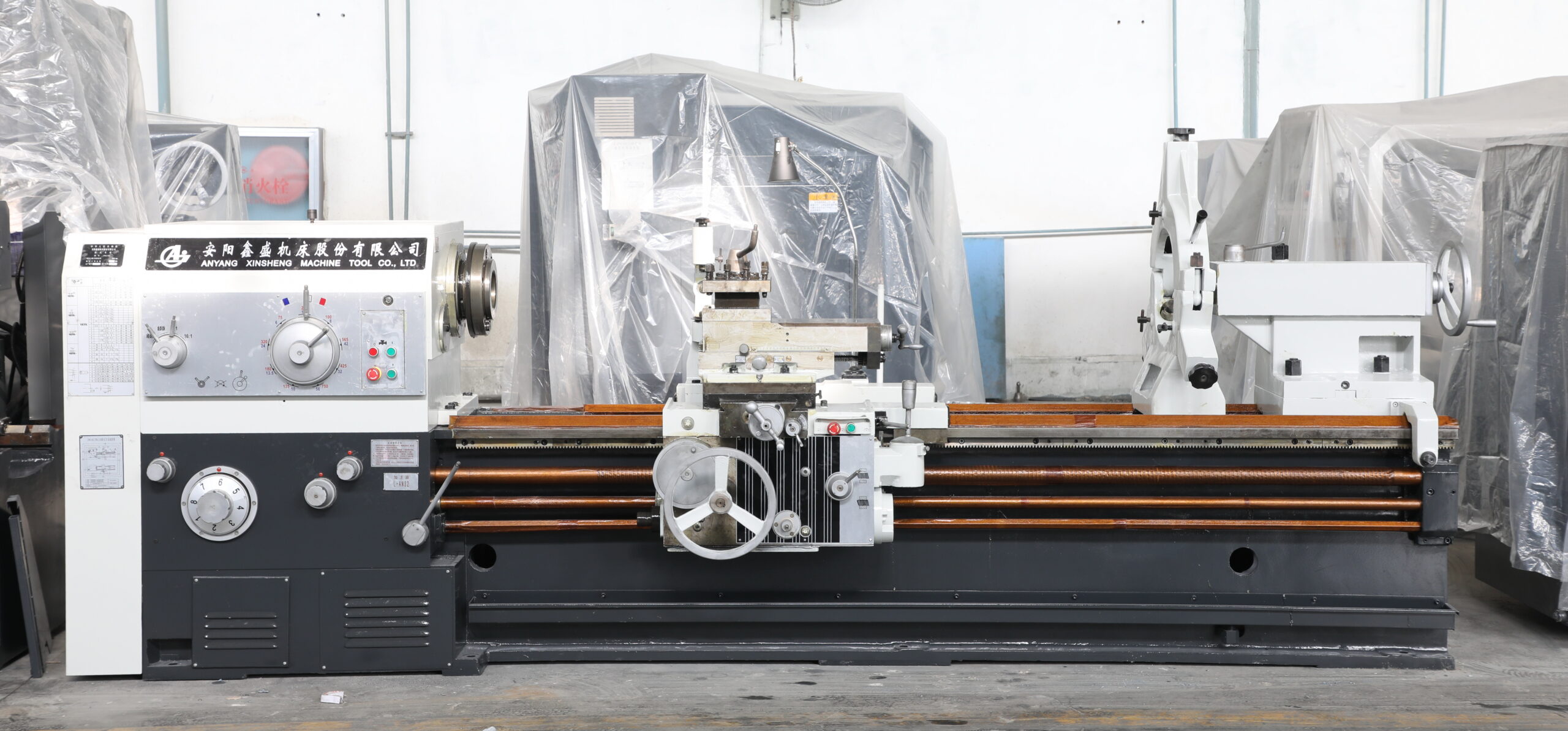

Home » Conventional horizontal lathe » CW6180/61100 Standard Horizontal Lathe Series

Content

The CW6180/61100 series standard lathes are designed for turning internal and external cylindrical surfaces, conical surfaces, other rotary surfaces, and end faces. They are also capable of machining a wide range of standard threads, including metric, inch, module, and diametral pitch threads. Additional operations such as drilling, reaming, tapping, and keyway broaching can also be performed. These machines are suitable for machining materials such as steel, cast iron, and non-ferrous metals.

Machining Accuracy:

- Roundness error of precision-turned workpieces: ≤ 0.01 mm

- Cylindricity error over a 300 mm measured length: ≤ 0.04 mm

- Surface roughness (Ra): ≤ 2.5 μm

Main Structural Features:

- High-torsional-rigidity flat-bed structure, made of high-quality cast iron. The guideways are induction-hardened and precision ground, with a width of 600 mm.

- The guideway pair uses a wear-resistant, vibration-damping, and precision-retaining structure, consisting of guideways lined with PTFE (polytetrafluoroethylene) soft belts.

- The spindle features a three-point support structure, offering high rigidity and precision, enabling heavy-duty cutting. It is equipped with a large through-hole of Φ100 mm.

- 18-step wide speed range allows for the selection of optimal spindle speeds.

- Capable of directly cutting both metric and inch threads without changing gears.

The carriage is equipped with a rapid traverse mechanism for enhanced efficiency

Inquiry

More Conventional horizontal lathe